Njengoba sonke sazi, izakhiwo ngokuvamile kulindeleke ukuthi zibe nempilo yenkonzo okungenani iminyaka engama-50. Ngakho-ke, izinto ezisetshenzisiwe kufanele futhi zibe nempilo yenkonzo ende. I-Silicone Sealant isetshenziswe kabanzi emkhakheni wokwakha amanzi ngisho nokuvalwa kwamanzi ngenxa yokumelana kwayo okuphezulu kakhulu nokuphansi okuphansi, ukumelana nesimo sezulu esivelele, kanye nezakhiwo ezinhle ze-bonding. Kodwa-ke, ngemuva kwesikhathi esilandela ukwakhiwa, ukwakhiwa kwe-silicone sealant sekuyinkinga ejwayelekile, eshiya imigqa "esheshayo ebhilidini.

Kungani i-silicone glue ishintsha umbala ngemuva kokusebenzisa?

Kunezizathu eziningi zokuhlukaniswa okuyingxenye noma okuphelele kwe-silicone tunginel sealant noma glue glue, ikakhulukazi ezicini ezilandelayo:

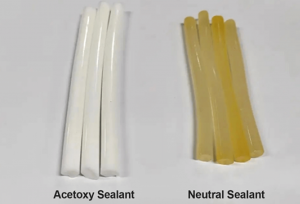

1. Ukungalingani kwezinto ezisetshenziswayo ezihlukene ze-sealant sealants, ama-sealants asuselwa ku-alcohol aregral, kanye nama-sealants angathathi hlangothi ngeke asetshenziswe ndawonye, ngoba angathintana futhi adale ukuguquguquka. I-Acidic Glass Sealants ingadala ama-sealants asuselwa ku-oxime aphenduka aphuzi, futhi asebenzise ama-batal asuselwa ku-agral aregral asuselwa ku-okotha aphansi futhi angathathi hlangothi ndawonye angabangela ophuzi.

Ama-molecule akhishwe ngesikhathi sokwelashwa kwama-balants angathathi hlangothi, -C = n-Oh, angaphendula ngama-acino azokwakha umoya-mpilo emoyeni ukwakha izinto ezinemibala.

2. Ukuxhumana neRubber nezinye izinto zokwakha

Ama-sealants abicone angaphenduka aphuzi lapho uthintana ngqo nezinhlobo ezithile zenjoloba, njengenjoloba yemvelo, irabha le-neoprene, nerabha le-EPDM. Lawa ma-rubber asetshenziswa kabanzi ezindongeni zamakhethini kanye namawindi / eminyango njengemichilo yenjoloba, ama-gaskets nezinye izinto. Le disceloration ibonakala ngokungalingani, kanye nezingxenye kuphela ezithintana ngqo nerabha elijika eliphuzi ngenkathi ezinye izindawo zihlala zingasebenzi

I-3. I-Sealant Discoloration nayo ingabangelwa ukwelula ngokweqile

Le nto ivame ukubalwa ngephutha ukulahleka kombala kwe-sealant, okungabangelwa yizinto ezintathu ezijwayelekile.

1) I-sealant esetshenzisiwe idlule ikhono layo lokuhlanyanisa futhi okuhlanganisiwe kweluliwe ngokweqile.

2) Ubukhulu be-sealant ezindaweni ezithile buncanyana kakhulu, okuholela ekushintsheni kombala okugxilwe kuwo kulezo zindawo.

I-4. I-discoloration of sealant nayo ingadalwa yizici zezemvelo.

Lolu hlobo lwe-discoloration luvame kakhulu ku-neutral-Type Ladabs, kanye nesizathu esiyinhloko sokuba khona kwe-discoloration ukuba khona kwezinto ezi-acidic emoyeni. Kunemithombo eminingi yezinto ezi-acidic emoyeni, njengokuphulukisa i-silicone sealant, izimbobo ze-acrylic ezisetshenziswa eSulphur Dioxide emkhathini, zivutha indle yepulasitiki, nokuningi. Zonke lezi zinto ezine-acidic emoyeni zingadala ama-sealants okotshani we-oximes ukuze ahlukanise.

Ungakugwema kanjani ukwakheka kwe-silicone sealant?

1) Ngaphambi kokwakha, yenza isivivinyo sokuhambisana kwezinto ezithintana ne-sealant ukuqinisekisa ukuhambisana phakathi kwezinto zokwakha, noma khetha izinto zensimbi ezihambisanayo, njengokukhetha izinto ezihambisanayo zenjoloba esikhundleni se-crubber imikhiqizo.

2) Ngesikhathi sokwakha, i-neutral sealant akufanele ithinte ne-acid sealant. Izinto ze-Amine ezikhiqizwe ukubola kwe-neutral sealant ngemuva kokuhlangana ne-acid kuzokwenza umoya emoyeni futhi kubangele ukuguquguquka.

3) Gwema ukuxhumana noma ukuvezwa kwe-sealant ezindaweni ezonakalisayo ezifana nama-acids ne-alkalis.

4) Ukudilizwa ikakhulukazi kwemikhiqizo enemibala emhlophe ekhanyayo, emhlophe, nasekubonakaleni. Ukukhetha ama-sealants amnyama noma amnyama kunganciphisa ingozi yokuqothuka.

5) Khetha ama-sealants ngekhwalithi eqinisekisiwe kanye nedumela elihle lomkhiqizo-junbond.

Isikhathi sePosi: Meyi-22-2023